Industrial machines play a crucial role in increasing productivity and efficiency in various sectors. From manufacturing plants to warehouses, these machines are essential for streamlining operations and maximizing output. In this article, we will explore the top 10 industrial machines that can help businesses enhance their productivity.

1. CNC Machines

CNC (Computer Numerical Control) machines are used in the manufacturing industry to automate the production of intricate parts and components. These machines use computer software to control the cutting and shaping of materials, resulting in higher precision and faster production times.

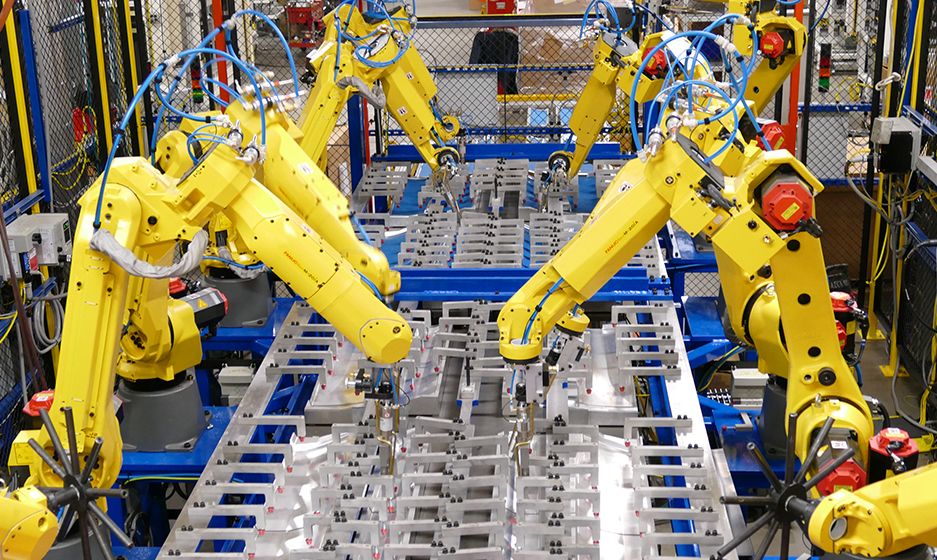

2. Robotics Systems

Robotics systems are becoming increasingly common in industrial settings due to their ability to perform repetitive tasks with speed and accuracy. These machines can handle a wide range of tasks, from assembly to packaging, and can operate 24/7 without fatigue.

3. Automated Guided Vehicles (AGVs)

AGVs are self-driving vehicles that are used to transport materials and goods in warehouses and manufacturing facilities. These machines can navigate complex environments autonomously, reducing the need for manual labor and increasing efficiency.

4. 3D Printers

3D printers are revolutionizing the manufacturing industry by allowing businesses to quickly prototype and produce custom parts and products. These machines can create complex geometries with ease, reducing production costs and lead times.

5. Packaging Machines

Packaging machines are essential for automating the packaging process and ensuring that products are properly sealed and labeled. These machines can handle a high volume of packaging tasks, freeing up employees to focus on other important tasks.

6. Conveyor Systems

Conveyor systems are used to transport materials and products throughout a facility, reducing the need for manual handling and streamlining the production process. These machines can move large quantities of goods quickly and efficiently.

7. Industrial Robots

Industrial robots are versatile machines that can perform a wide range of tasks, such as welding, painting, and material handling. These machines can operate in hazardous environments and work alongside human employees to increase productivity.

8. Laser Cutting Machines

Laser cutting machines are used to cut and shape a variety of materials, including metal, plastic, and wood. These machines offer high precision and fast cutting speeds, making them ideal for industries that require intricate designs and tight tolerances.

9. Assembly Line Machines

Assembly line machines are designed to automate the assembly process by combining multiple tasks into a single production line. These machines can significantly increase production rates and reduce labor costs for businesses.

10. ERP Software

ERP (Enterprise Resource Planning) software is essential for managing and optimizing the production process. This software can track inventory, schedule production orders, and monitor performance metrics, helping businesses make informed decisions to improve productivity.

Conclusion

Investing in the right industrial machines can have a significant impact on a business’s productivity and profitability. From CNC machines to robotics systems, these machines offer a wide range of capabilities to help streamline operations and increase output. By incorporating these top 10 industrial machines into their facilities, businesses can stay competitive in today’s fast-paced market.